Water Bottle Making Machines

765000.00 INR

Product Details:

- Operating Temperature 37C to 45C

- Machine Type Automatic Bottle Blowing Machine

- Voltage 220V

- Features Durable High Efficiency Easy to Operate

- Control System PLC Control System

- Lubricating System Automatic Lubrication

- Frequency 50 Hz

- Click to view more

X

Water Bottle Making Machines Price And Quantity

- 765000.00 INR

- 10

Water Bottle Making Machines Product Specifications

- 10-15 kg/cm

- Grey and White

- 450 Kg

- Advanced Cooling System

- Low Noise

- Wired

- Automatic

- Electricity

- High precision

- 1 Year

- Metal Frame

- 1000-1500 bottles/hour

- 5 kW

- PLC Control System

- 1200 x 600 x 1800 mm

- Durable High Efficiency Easy to Operate

- 37C to 45C

- Manufacturing Plastic Water Bottles

- 220V

- Automatic Bottle Blowing Machine

- Water Bottle Making Machines

- Blow Molding Technology

- Electric

- 50 Hz

- Powder Coated

- Automatic Lubrication

Product Description

Water Bottle Making Machines

Product details

|

Raw Material |

PET Preform |

|

Brand |

Dharmanandan |

|

Power Consumption |

36 HP |

|

Production Capacity |

1100/hr |

|

Automation Grade |

Semi Automatic |

|

Phase |

3 |

|

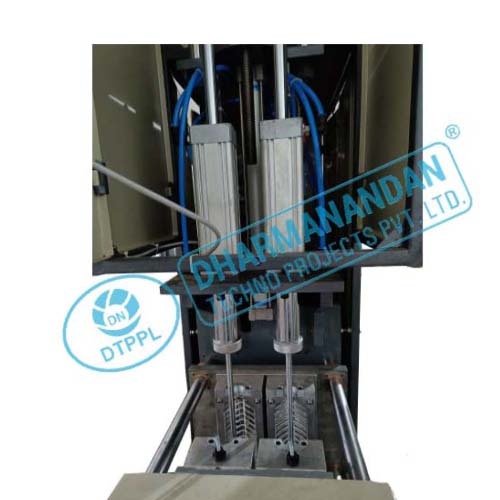

Mould Cavity |

2 |

Advanced Cooling Technology

Equipped with a dedicated cooling system, this water bottle making machine ensures optimal mold temperature during high-volume production. This results in consistent bottle quality and reduces the risk of deformation, while also prolonging machine life. The cooling mechanism supports efficient operation even during extended production runs and helps maintain stable operating temperatures from 37C to 45C.

High Precision and Efficient Control

Utilizing a sophisticated PLC control system, the machine delivers high accuracy and repeatability in bottle thickness and shape. Operators benefit from intuitive controls and real-time monitoring, enhancing productivity and minimizing errors. The automatic lubrication and responsive design further contribute to smooth performance and maintenance simplicity.

Noise-Reducing and Durable Design

The machine operates with low noise levels, making it suitable for factories where a comfortable work environment is important. Powder-coated metal framing provides durability and resistance to wear, while its compact dimensions (1200 x 600 x 1800 mm) ensure ease of installation and maintenance in industrial settings.

FAQ's of Water Bottle Making Machines:

Q: How does the advanced cooling system benefit the bottle production process?

A: The cooling system efficiently maintains optimal mold temperatures between 37C to 45C, preventing bottle deformities and enhancing production consistency and machine longevity.Q: What type of control system is used in this machine, and how does it improve operations?

A: The machine utilizes a PLC control system, providing precise automation, easy programming, and accurate monitoring of the production parameters, resulting in high-quality bottle output with minimal operator intervention.Q: When is the optimal time to perform regular maintenance on this machine?

A: Routine checks and maintenance are recommended after every production shift or as outlined in the manufacturer's manual. The automatic lubrication system simplifies ongoing care, helping prevent wear and extending machine lifespan.Q: Where is this water bottle making machine commonly installed?

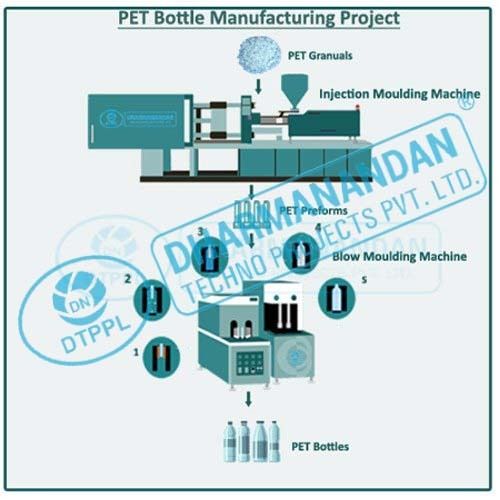

A: It is ideal for installation in manufacturing plants, factories, or industrial workshops, especially those involved in plastic bottle production and packaging in India.Q: What is the process of manufacturing bottles with this machine?

A: The machine relies on blow molding technology to shape molten plastic into bottles under high pressure (10-15 kg/cm2), with precise temperature and pressure control managed by the automated PLC system for consistent output.Q: How does the machine support high-volume production needs?

A: With a capacity of 1,000-1,500 bottles per hour and an efficient automatic operation, it meets the requirements of large-scale manufacturing while maintaining durability and easy operability.Q: What warranty and support are provided with the machine?

A: The machine comes with a 1-year warranty, and support is available for installation, operation, and maintenance through distributor, exporter, manufacturer, and service provider channels in India.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Other Products in 'Bottle Making Machine' category

|

DHARMANANDAN TECHNO PROJECTS PVT. LTD.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |