Pet Bottling Machine

1500000.00 INR

Product Details:

- Frequency 50-60 Hz

- Cooling System Inbuilt Cooling

- Machine Type Pet Bottling Machine

- Connectivity Options Optional USB/RS485 interface

- Production Capacity 2000-12000 bottles per hour

- Noise Level Low (< 75 dB)

- Power Rating 3 Phase

- Click to view more

X

Pet Bottling Machine Price And Quantity

- 1500000.00 INR

- 10

Pet Bottling Machine Product Specifications

- 2400 x 1200 x 2500 mm

- 3-6 kW

- Compact design, high-efficiency, easy operation and maintenance

- 1%

- 380V/220V, 50/60 Hz

- 3 Phase

- Low (< 75 dB)

- PLC Automation

- Pet Bottling Machine

- 2000-12000 bottles per hour

- Optional USB/RS485 interface

- Automatic

- 1200 kg (Approx)

- Blue & Silver

- Automatic Bottling Machine

- Inbuilt Cooling

- 50-60 Hz

- Servo/Geared Motor

- For filling and packaging PET bottles mineral water, juice, carbonated drinks

- Paint Coated / Stainless Steel

- PET

- Stainless Steel Frame

- PLC with Touch Screen

- 5C - 40C

- PBM-2023

- Automatic Centralized Lubrication

- 0.6-0.8 MPa

- 2-3 HP

- Electric

Pet Bottling Machine Trade Information

- Eastern Europe, Middle East, Africa, Asia, Western Europe

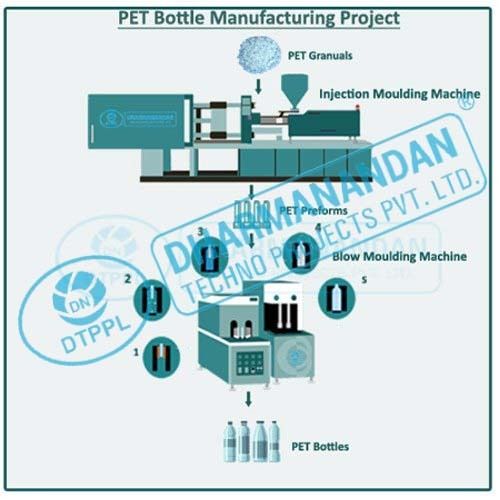

Product Description

Pet Bottling Machine provided by us, is a machine which is used to make the pet bottles in a proper manner. This machine find their applications in industries concerned with the packaging of liquids. This machine is also known for its unique features like high quality, excellent performance, reliable operations, and better durability. Pet Bottling Machine finds its application in various industries for different usage. This machine is very easy to use and safe too. This machine is very effective as well as economical to use.

Superior Filling Technology for PET Bottles

The PBM-2023 adopts advanced gravity and counter pressure filling methods, offering unparalleled precision (1%) and adaptability from 200ml to 2L bottles. With flexible nozzle configurations between 6 and 24, this machine caters to variable production requirements. Its integrated rinsing, filling, and capping stations streamline workflow, ensuring each bottle is processed with safety and hygiene as top priorities.

Efficient and User-Friendly Operation

Designed with automation in mind, the PBM-2023 features a PLC control system with a user-friendly touch screen interface. Changeovers are simple and fast, taking less than 30 minutes. Adjustable working speed, automatic lubrication, and anti-vibration mounts minimize downtime, while integrated safety features such as emergency stop, interlocks, and alarms maximize operator and product safety during every shift.

Durability and Hygiene for Demanding Environments

Constructed with food-grade stainless steel (SS 304/316) and a robust stainless steel frame, the PBM-2023 stands up to rigorous industrial use while maintaining strict hygienic standards. The inbuilt cooling system keeps operations steady from 5C to 40C, supporting the bottling of a wide range of beverages at filling temperatures up to 85C. Compact, durable, and low-noise, it is engineered for reliable performance and easy maintenance.

FAQs of Pet Bottling Machine:

Q: How does the PBM-2023 Pet Bottling Machine ensure accuracy in filling?

A: The PBM-2023 utilizes gravity or counter pressure filling, managed by a PLC system, to ensure precise liquid measurement with an accuracy of 1%. Its touch screen control and calibrated nozzles also contribute to consistent, accurate bottle filling across all accepted bottle sizes.Q: What bottle sizes and types are compatible with this machine?

A: This machine supports PET bottles from 200ml to 2L and accommodates standard 28mm and 30mm neck types. Changeovers between different bottle sizes are rapid, taking less than 30 minutes, making it ideal for producers handling multiple bottle formats.Q: When is it necessary to adjust the machines filling speed?

A: The filling speed can be adjusted directly via the touch screen interface, allowing operators to match different production targets. Adjusting speed is especially useful when switching between bottle volumes, beverage types, or to optimize workflow in response to order demands.Q: Where can the PBM-2023 be installed and used?

A: With a compact footprint and integrated anti-vibration mounts, the PBM-2023 is suitable for various factory settings, whether for mineral water, juice, or carbonated drink bottling. Its sturdy stainless steel build and adjustable conveyor make it adaptable for use in beverage factories and packaging facilities.Q: What is the process flow in this bottling machine?

A: The process begins with bottles entering the integrated multi-head rinser for cleaning, followed by automated filling through gravity or counter pressure, then rotary chuck capping. All steps are synchronized and monitored through PLC automation, with inbuilt systems for cooling, lubrication, and safety.Q: How does the machine promote operator safety and product quality?

A: The PBM-2023 incorporates comprehensive safety featuresemergency stop buttons, interlocks, overload and short circuit protection, and visual/audible alarms. Food-contact parts use certified stainless steel, upholding food safety and cleanliness with every production run.Q: What are the main benefits of using the PBM-2023 Pet Bottling Machine?

A: Operators benefit from high efficiency (up to 12,000 bottles/hour), easy maintenance, minimal changeover times, quiet operation, robust safety systems, and reliable product quality. Its adaptable design makes it an excellent investment for growing beverage producers in India and internationally.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Other Products in 'Bottle Making Machine' category

|

DHARMANANDAN TECHNO PROJECTS PVT. LTD.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |