Soda Water Plant

Soda Water Plant Specification

- Efficiency (%)

- 97%

- Driven Type

- Electric Motor

- Production Capacity

- Up to 2400 bottles per hour

- Model No

- SWP-2500

- Usage & Applications

- For Soda/Carbonated Water Bottling

- Frequency

- 50-60 Hz

- Temperature Range

- 5C - 40C

- Accessories

- CO2 Regulator, Bottle Rinser, Filling Heads

- Speed

- Adjustable

- Motor Power

- 3 HP

- Plastic Processed

- Not Applicable (Glass/PET Bottles)

- Installation Guideline

- Onsite Installation Assistance Provided

- Automation Grade

- Fully Automatic

- Type

- Fully Automatic Soda Water Plant

- Material

- Stainless Steel

- Computerized

- Yes

- Automatic Grade

- Automatic

- Control System

- PLC Controlled

- Drive Type

- Electric

- Voltage

- 380V

- Power

- 3.5 kW

- Weight (kg)

- 1200 kg

- Dimension (L*W*H)

- 3200 mm x 1100 mm x 2200 mm

- Color

- Silver

- Capacity

- 2000-2500 Bottles/Hour

- Features

- Corrosion Resistance, Low Maintenance, High Output, Robust Design

- Power Consumption

- 3.5 kW/hr

- Surface Finish

- Polished

- Machine Type

- Automatic Carbonated Drink Filling Machine

- Climate Suitability

- Tropical and Temperate Zones

- Cleaning System

- CIP (Clean-In-Place) Compatible

- Noise Level

- Below 70 dB

- Startup Time

- 10 minutes

- Filling Nozzles

- 6

- Packaging Type

- Wooden Crates for Transport

- Recommended Operators

- 2 persons per shift

- Maintenance Requirement

- Low

- Operating Pressure

- 0.6-0.8 Mpa

- Bottle Size Range

- 200 ml 2000 ml

- Safety Features

- Overload Protection, Safety Interlocks

- Bottle Type Supported

- Glass & PET Bottles

- Filling Accuracy

- 2 ml

- Capping System

- Automatic Screw/Press Capper

- Water Usage

- Approx. 600 liters/hour

- Lubrication

- Automatic Centralized Greasing

Soda Water Plant Trade Information

- Minimum Order Quantity

- 10 Units, Unit

- Main Export Market(s)

- Middle East, Africa, Eastern Europe, South America, Asia

About Soda Water Plant

Precision Soda Water Plant for Diverse Applications

The SWP-2500 Soda Water Plant is tailored for industries requiring potent, efficient bottling of soda and carbonated water. Built with stainless steel, it ensures durability and hygiene. Its PLC-controlled automation and advanced filling technology support both Glass and PET bottles with precise filling, automatic greasing, and comprehensive safety interlocks. Perfect for large-scale production, the plant delivers high output at 97% efficiency, making it a top choice for beverage manufacturers in tropical and temperate regions alike.

Packaging, Certification, and Expenditure Policies

Each Soda Water Plant is shipped in sturdy wooden crates for secure transit. Stock is ready for immediate dispatch, ensuring minimized expenditure on waiting time. We offer flexible sample policies and provide installation guidance onsite for seamless commissioning. The plant is backed by required certifications, guaranteeing quality and compliance. Accessory packs, such as CO2 regulators and bottle rinsers, are included to streamline your startup process and increase operational value right from day one.

FAQs of Soda Water Plant:

Q: How does the SWP-2500 Soda Water Plant ensure precise filling for different bottle sizes?

A: The SWP-2500 uses PLC-controlled automatic filling nozzles, accommodating both Glass and PET bottles ranging from 200 ml to 2000 ml. It maintains high filling accuracy within 2 ml, ensuring consistent product quality.Q: What type of maintenance does the Soda Water Plant require?

A: Thanks to its low maintenance design and automatic centralized greasing, routine upkeep is minimal. Cleaning is simplified with the CIP (Clean-In-Place) compatibility, making the plant easy to maintain for ongoing efficiency.Q: When is the machine ready for production after installation?

A: The startup time is remarkably fastwithin just 10 minutes after setup, the plant is ready to begin full-scale operations, offering rapid response to production demands.Q: Where can the plant be installed and used?

A: The plant is suitable for a variety of environments, engineered to operate reliably in both tropical and temperate zones. Onsite installation assistance is available for optimal commissioning and training.Q: What benefits does the automatic capping system provide?

A: The automatic screw or press capping system increases productivity, minimizes operator workload, and ensures secure capping, which is critical for maintaining carbonation integrity and hygiene.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Soft Drink Plant Category

Soda Plant

Price 1000000 INR

Minimum Order Quantity : 10 Units, Unit

Usage & Applications : Beverage Industry, Soft Drink Manufacturing

Frequency : 50 Hz

Type : Soda Plant

Voltage : 220380 V

Soft Drink Plant

Price 1000000.00 INR

Minimum Order Quantity : 10

Usage & Applications : Carbonated Drinks, Soft Drinks, Soda Water

Frequency : 50/60 Hz

Type : Soft Drink Plant

Voltage : 220440 V

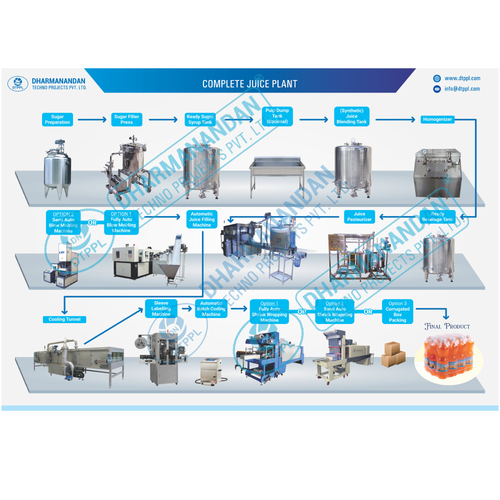

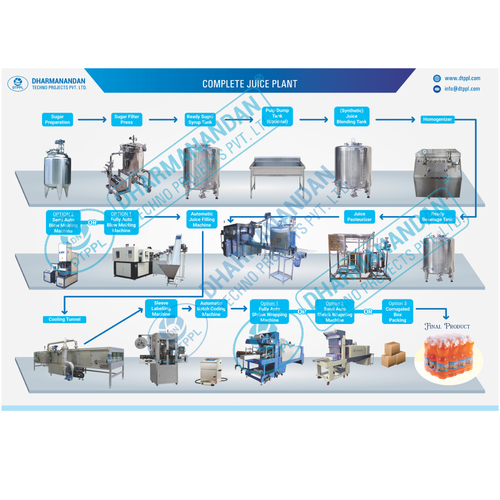

Juice Plant Projects

Price 1000000 INR

Minimum Order Quantity : 10 Units, Unit

Usage & Applications : Juice Extraction and Processing

Frequency : 5060 Hz

Type : Juice Plant Projects

Voltage : 380440 Volt (v)

Fruit Juice Processing Plant

Price 1000000 INR

Minimum Order Quantity : 10

Usage & Applications : Fruit juice extraction, filtration, pasteurization, filling, and packaging.

Frequency : 50 Hz

Type : Fruit Juice Processing Plant

Voltage : 380V / 415V

|

DHARMANANDAN TECHNO PROJECTS PVT. LTD.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry

Call Me Free

Call Me Free