Soda Plant

1000000 INR

Product Details:

- Motor Power 3 HP

- Frequency 50 Hz

- Automation Grade Semi-Automatic

- Driven Type Mechanical

- Speed Adjustable

- Plastic Processed PET bottles

- Efficiency (%) 98%

- Click to view more

X

Soda Plant Price And Quantity

- 10 Unit

- 1000000 INR

- 0.5%

- Indoor/Industrial

- ISI, CE certified

- 0.6 0.8 MPa

- CIP (Clean In Place) Compatible

- SS304 Food Grade

- Integrated with Precise Control

- Adjustable Stainless Steel Legs

- 15 minutes

- Below 72 dB

- 1-2 persons

- 1500 Liters/Day

- Standard Export Worthy Packing

- Emergency Stop, Overload Protection, Safety Guards

- 200 ml to 2 Liter

Soda Plant Product Specifications

- No

- Mechanical

- Adjustable

- Stainless Steel

- Polished

- High Performance, Low Maintenance, Durable Construction, User Friendly, Corrosion Resistant

- Electric

- Semi-Automatic

- PLC Controlled

- 3 HP

- 50 Hz

- 220-380 V

- Semi-Automatic

- 2000-6000 bottles/hr

- SP-6000

- Beverage Industry, Soft Drink Manufacturing

- Filling and Carbonation

- 3200 kg

- 5-10 kW

- 4C 18C

- Silver

- Soda Plant

- 6 kW/hr

- 7000 bottles/day

- PET bottles

- CO2 Cylinder, Filler Valves, Sensor, Conveyor

- 98%

- 6000 x 1500 x 2100 mm

- On-Site installation with engineer support

- 0.5%

- Indoor/Industrial

- ISI, CE certified

- 0.6 0.8 MPa

- CIP (Clean In Place) Compatible

- SS304 Food Grade

- Integrated with Precise Control

- Adjustable Stainless Steel Legs

- 15 minutes

- Below 72 dB

- 1-2 persons

- 1500 Liters/Day

- Standard Export Worthy Packing

- Emergency Stop, Overload Protection, Safety Guards

- 200 ml to 2 Liter

Soda Plant Trade Information

- Western Europe, Middle East, Africa, Eastern Europe, Asia

Product Description

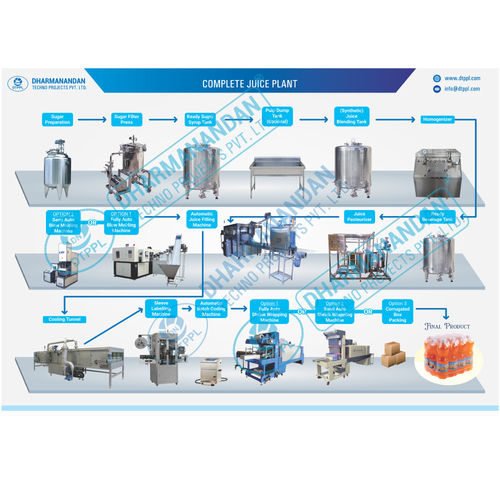

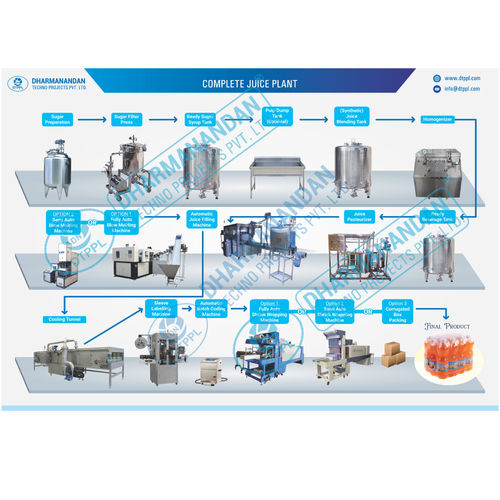

Discover the acclaimed SP-6000 Soda Plant a trending solution in beverage technology, renowned for its classic blue-ribbon performance and precision. This semi-automatic, PLC-controlled machine supports versatile bottle sizes from 200 ml to 2 Liter, boasting a filling accuracy of 0.5%. Crafted from SS304 food-grade stainless steel, its corrosion-resistant build ensures low maintenance and lasting durability. Integrated carbonation with precise control, CIP-compatible cleaning, safety features, and adjustable speed make it a user-friendly choice for the beverage industry. Perfect for manufacturers seeking excellence and reliability.

Versatile Soda Plant for Beverage Industry

This soda plant offers a comprehensive application media, perfectly suitable for the soft drink manufacturing sector. Used predominantly by beverage producers, distributors, and bottling facilities, it supports PET bottles with seamless filling and carbonation. Its classic mechanical-driven system ensures optimal efficiency in varied industrial environments, while the user-friendly design caters to semi-automatic type usage for consistent quality production.

Sample Availability & Reliable Supply Delivered Nationwide

Soda Plant samples are available for evaluation to ensure product suitability before order confirmation. With robust supply ability, manufacturers in India enjoy timely shipped goods and prompt arrival of units. The main domestic market encompasses key industrial zones, where standard export-worthy packing guarantees safe delivery. Goods are delivered with comprehensive support from installation engineers for smooth onboarding.

Versatile Soda Plant for Beverage Industry

This soda plant offers a comprehensive application media, perfectly suitable for the soft drink manufacturing sector. Used predominantly by beverage producers, distributors, and bottling facilities, it supports PET bottles with seamless filling and carbonation. Its classic mechanical-driven system ensures optimal efficiency in varied industrial environments, while the user-friendly design caters to semi-automatic type usage for consistent quality production.

Sample Availability & Reliable Supply Delivered Nationwide

Soda Plant samples are available for evaluation to ensure product suitability before order confirmation. With robust supply ability, manufacturers in India enjoy timely shipped goods and prompt arrival of units. The main domestic market encompasses key industrial zones, where standard export-worthy packing guarantees safe delivery. Goods are delivered with comprehensive support from installation engineers for smooth onboarding.

FAQs of Soda Plant:

Q: How does the SP-6000 Soda Plant maintain filling accuracy?

A: The SP-6000 employs advanced PLC control and precise filler valves, ensuring a reliable filling accuracy of 0.5% across all bottle sizes, enhancing efficiency and minimizing product wastage.Q: What is the typical process for installing this soda plant?

A: Installation is conducted on-site with support from skilled engineers, ensuring correct setup of all mechanical, electrical, and carbonation systems for optimal performance and safety standards compliance.Q: Where can this soda plant be used most effectively?

A: It is ideal for industrial indoor environments, especially soft drink manufacturing units and beverage facilities requiring high-speed, efficient PET bottle filling and carbonation.Q: When are soda plant samples typically delivered after order placement?

A: Sample availability is confirmed upon request, and shipped goods usually arrive within a negotiated delivery timeline depending on location and order volume.Q: What safety features are included in the SP-6000 Soda Plant?

A: This acclaimed system comes equipped with emergency stop mechanisms, overload protection, safety guards, and adheres to ISI and CE standards, ensuring operational safety for users.Q: How does the integrated carbonation system benefit the user?

A: The integrated carbonation system enables precise CO2 control, delivering consistently well-carbonated beverages while simplifying production and reducing maintenance downtime for the operator.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Other Products in 'Soft Drink Plant' category

|

DHARMANANDAN TECHNO PROJECTS PVT. LTD.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Call Me Free

Call Me Free