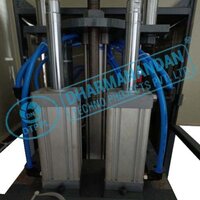

PET Stretch Blowing Machine

765000 INR

Product Details:

- Product Type PET Stretch Blowing Machine

- General Use Manufacturing PET bottles and containers

- Material Stainless Steel, Alloy Steel

- Capacity 2000-2200 bottles per hour (based on bottle size and cavity)

- Weight (kg) Approx. 1200 kg

- Type Automatic Bottle Blowing Machine

- Computerized Yes

- Click to view more

X

PET Stretch Blowing Machine Price And Quantity

- 10

- 765000 INR

PET Stretch Blowing Machine Product Specifications

- 18 kW

- Yes

- High efficiency, low energy consumption, easy to operate

- Blue/White

- 1.5 m/min

- 2 Cavities

- Stretch Blow Moulding

- Yes, integrated

- 2000-2200 bottles per hour (based on bottle size and cavity)

- Approx. 1200 kg

- 450 mm

- 2.0 m/min

- 2100 mm x 800 mm x 2200 mm

- Stainless Steel, Alloy Steel

- PET Stretch Blowing Machine

- 140 mm

- 370 mm

- Yes

- 380V, 50Hz

- 38 kN

- Manufacturing PET bottles and containers

- Automatic Bottle Blowing Machine

PET Stretch Blowing Machine Trade Information

- Western Europe, Middle East, Asia, Africa

Product Description

PET Stretch Blowing Machine

Specification

|

|

Description |

Specification |

|

|

Capacity |

200 ml to 2000 ml (Neck Dia. 25mm to 38mm ) |

|

|

Production Capacity |

1100 & 1200 BPH |

|

Mould |

Max. Mould thickness |

150 MM |

|

|

Min. Mould thickness |

140 MM |

|

|

Clamping force |

8 Ton |

|

Oven |

Number of Preform Holders |

74 |

|

|

Number of Heating modules |

1 |

|

|

Number of Heating zones |

6 |

|

|

Lamp Power |

2000 W |

|

|

Lamp length |

1120 MM |

|

Stretching |

Number of stretch Rods |

2 |

|

|

Stretching stroke Max. |

400 MM |

Superior Production Capacity and Flexibility

This automatic stretch blow molding machine delivers an impressive throughput of up to 2200 bottles per hourperfect for medium to large-scale production lines. Accommodating bottle volumes from 200 ml to 2000 ml and a neck diameter range of 16 mm to 38 mm, it easily adapts to a diverse range of packaging needs across various industries.

User-Friendly Operation with Robust Safety and Control

Operating the PET Stretch Blowing Machine is straightforward, thanks to a modern PLC touch screen that streamlines process management. Integrated safety features such as a door interlock, emergency stop, and overheat protection further ensure safe operation. The ergonomic design ensures low noise levels and minimal operator fatigue.

Reliable Performance and Minimal Maintenance

Built from top-grade stainless and alloy steel, this machine features a centralized automatic lubrication system and water cooling, ensuring dependable, low-maintenance operation even in demanding environments. Mould changes can be completed within 30 minutes, reducing downtime and maximizing productivity.

FAQs of PET Stretch Blowing Machine:

Q: How does the PET Stretch Blowing Machine accommodate different bottle sizes and neck diameters?

A: The machine supports bottle volumes between 200 ml and 2000 ml and neck diameters from 16 mm to 38 mm, making it ideal for a variety of PET bottle applications. Adjustment for different sizes and quick mold change (within 30 minutes) enable flexible production.Q: What are the benefits of the machines water cooling and lubrication system?

A: The advanced water cooling system maintains optimal operating temperatures, ensuring product consistency and prolonging machine life. Its centralized automatic lubrication minimizes wear, reduces maintenance needs, and keeps performance efficient.Q: When is maintenance required for this stretch blowing machine?

A: Thanks to its low-maintenance design, routine checks and scheduled servicing according to the manufacturers guidelines are usually sufficient. Automatic lubrication and robust materials contribute to extended maintenance intervals.Q: Where is this machine most effectively used?

A: This stretch blow molding machine is well-suited for production environments requiring high efficiency and versatility, such as beverage, cosmetic, pharmaceutical, and packaged water industries. It caters to manufacturers, suppliers, exporters, and wholesalers across India.Q: What is the process for loading preforms into the machine?

A: Preform loading can be done either manually or automatically, depending on your setup. Both methods ensure smooth feeding into the blowing section for streamlined and consistent bottle manufacturing.Q: How does the machine ensure operator safety during operation?

A: Safety is prioritized through integral features like a door interlock system, emergency stop controls, and overheat protection. These prevent accidents, halt machine operation during malfunctions, and protect both operators and equipment.Q: What are the primary benefits of using this automatic PET bottle blowing machine?

A: Key advantages include high production rates of up to 2200 bottles per hour, low energy consumption, easy operation through PLC touch screen controls, quick mold change, and a quiet, safe work environmentall contributing to a highly productive and cost-effective manufacturing process.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Other Products in 'Blowing Machine' category

|

DHARMANANDAN TECHNO PROJECTS PVT. LTD.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Call Me Free

Call Me Free