Bottle Blowing Machine

765000 INR

Product Details:

- Product Type Bottle Blowing Machine

- General Use Manufacturing PET Bottles

- Material PET

- Capacity 1200-1500 bottles/hour

- Weight (kg) 1500 kg

- Type Fully Automatic

- Computerized Yes

- Click to view more

X

Bottle Blowing Machine Price And Quantity

- 765000 INR

- 10

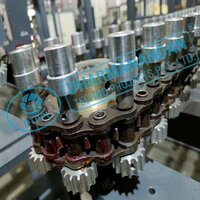

Bottle Blowing Machine Product Specifications

- Fully Automatic

- 60 kN

- 18 kW

- 1200-1500 bottles/hour

- 380 V

- Bottle Blowing Machine

- 370 mm

- Blue & Grey

- Yes

- 2200 x 900 x 1900 mm

- Manufacturing PET Bottles

- Yes

- 1.0 m/min

- 200 mm

- Yes

- 1500 kg

- PET

- Stretch Blow Moulding

- High Automation, Energy Saving

- 300 mm

- 2.0 m/min

- 2

Bottle Blowing Machine Trade Information

- Western Europe, Middle East, Eastern Europe, Asia, Africa

Product Description

Bottle Blowing Machine

Product details

|

Raw Material |

PET Preform |

|

Brand |

Dharmanandan |

|

Power Consumption |

36 HP |

|

Production Capacity |

1100/hr |

|

Automation Grade |

Semi Automatic |

|

Phase |

3 |

|

Mould Cavity |

2 |

Advanced Automation for Consistent Output

With high automation and a computerized PLC control system, this bottle blowing machine offers an output of 1200-1500 bottles per hour. The automated preform feeder and lubrication system simplify operation and reduce manual interventions, ensuring steady and repeatable production ideal for large-scale manufacturing.

Designed for Efficiency and Safety

The machine combines energy-saving features with essential safety systems, including emergency stop and overload/phase electrical protection. Its infrared heater, water-cooled environment, and low noise profile (<75 dB) ensure both efficiency and a safer workspace, suitable for a manufacturing facility of any size.

FAQs of Bottle Blowing Machine:

Q: How does the auto feeder system improve the bottle production process?

A: The auto feeder system automatically delivers preforms to the blow moulding area, minimizing manual handling and ensuring a continuous workflow. This increases efficiency, reduces downtime, and streamlines the overall bottle manufacturing process.Q: What bottle sizes and neck diameters can this machine accommodate?

A: This machine is built to produce PET bottles with volumes from 0.25L to 2L and neck diameters ranging from 18 mm to 38 mm, offering flexibility for a wide array of beverage and packaging needs.Q: When should routine maintenance be performed on the machine?

A: Thanks to its automatic lubrication system and low-maintenance design, routine checks are minimal. Scheduled servicing can follow manufacturer guidelines, typically at intervals recommended based on production volume and hours of operation.Q: Where is the best installation location for this floor-mounted machine?

A: The bottle blowing machine should be installed on a level and stable floor in a well-ventilated production area with access to utilities like water and electricity. Its compact dimensions (2200 x 900 x 1900 mm) enable easy integration into most manufacturing layouts.Q: What is the process of manufacturing PET bottles with this fully automatic machine?

A: The process begins with automatic preform feeding, followed by infrared heating. The heated preform is stretched and blown into the mould using compressed air, forming bottles of desired sizes. The water cooling system then solidifies the shaped bottles quickly.Q: How does the integrated air compressor system benefit production?

A: Including both high and low pressure air compressors (2.0 m/min & 1.0 m/min), the machine ensures consistent air supply for efficient stretching and blowing, reducing dependency on external compressors and providing stable operation.Q: What are the primary benefits of using this particular bottle blowing machine?

A: Key benefits include high throughput, energy efficiency, consistent product quality, user-friendly controls, robust safety features, and versatility in bottle size. These factors make it suitable for distributors, exporters, manufacturers, and suppliers seeking reliable PET bottle production solutions.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Other Products in 'Blowing Machine' category

|

DHARMANANDAN TECHNO PROJECTS PVT. LTD.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Call Me Free

Call Me Free