Water Bottling Plant Machine

750000.00 INR/Unit

Product Details:

- Product Type Automatic

- Material SS 304/316

- Computerized Yes

- Automatic Grade Automatic

- Control System PLC Control

- Drive Type Mechanical

- Weight (kg) 1500-4000 Kilograms (kg)

- Click to view more

X

Water Bottling Plant Machine Price And Quantity

- 750000.00 INR/Unit

- 10 Unit

- 750000.00 - 3000000.00 INR/Unit

Water Bottling Plant Machine Product Specifications

- 1 year

- Automatic

- Yes

- 24-150bpm Kg/hr

- Mechanical

- PLC Control

- Silver

- 1500-4000 Kilograms (kg)

- 6*6*6 to 12*12*12 Foot (ft)

- Automatic

- SS 304/316

Water Bottling Plant Machine Trade Information

- Nhavaseva-Mumbai

- Letter of Credit (L/C), Telegraphic Transfer (T/T), Cheque

- 4 Unit Per Month

- 2 Months

- Contact us for information regarding our sample policy

- South America, Middle East, Africa, Asia

- All India

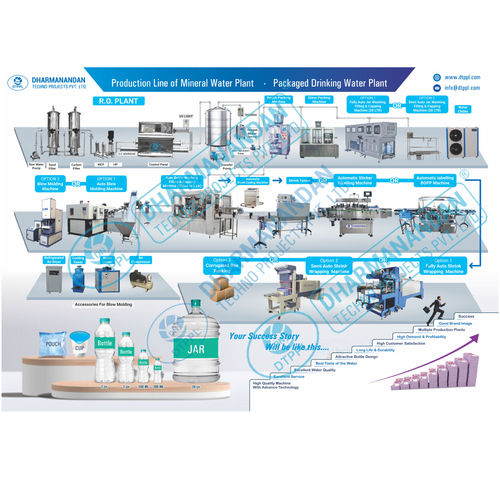

Product Description

The establishment in the year 2009, Dharmanandan Techno Projects Pvt Ltd are a renowned entity engaged in providing premium grade Bottling Plant Machine. The offered machine is extensively used for filling bottles in accurate quantity. With the use of top-notch quality components and sophisticated techniques, the offered Bottling Plant Machine is manufactured with precision under the supervision of dexterous professionals. Clients can easily avail the offered machine as per their requirements.

Features:

- High accuracy

- Advance Mechanical Technology

- PLC based Control

- No change Parts Need For varies in Volume

- Impeccable performance

- Sturdy design

- Smooth finish

Advanced Automation for Efficient Bottling

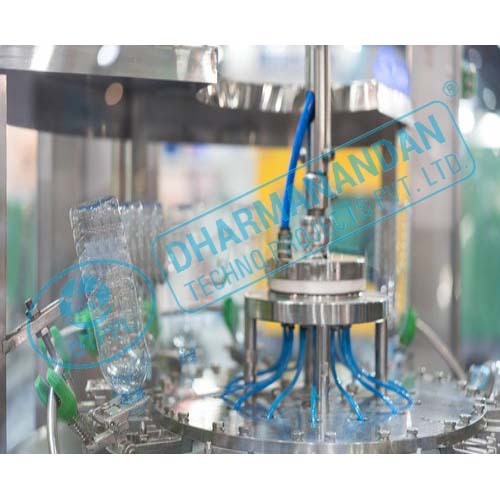

This water bottling plant machine is fully automatic and incorporates a PLC-controlled, computerized system, ensuring precise, efficient, and consistent operation. The mechanical drive design optimizes productivity and minimizes downtime, meeting the high standards required in modern beverage industries. With a capacity range up to 150 bottles per minute, it is ideal for businesses seeking to scale their bottled water operations.

Hygienic and Robust Stainless Steel Construction

The machine is manufactured using high-grade SS 304/316 stainless steel, making it corrosion-resistant and suitable for food-grade applications. This not only ensures strict hygiene standards but also offers longevity and durability even in intensive, continuous-use environments. The silver finish adds to its professional aesthetic.

Versatile Capacity and Footprint Options

Available in a variety of sizes, from 6x6x6 to 12x12x12 feet, our plant machine accommodates both compact and larger production settings. Its substantial weight (1500-4000 kg) stabilizes the unit, contributing to safety and seamless operation in industrial environments. The adjustable speed and bottle-per-minute output make it a flexible choice for expanding enterprises.

FAQ's of Water Bottling Plant Machine:

Q: How does the PLC control system improve the water bottling process?

A: The PLC (Programmable Logic Controller) enables automated and precise control over bottle filling, capping, and labeling. This computerized system enhances efficiency, reduces manual intervention, and ensures consistency in the production process.Q: What is the installation process for the Water Bottling Plant Machine?

A: Installation is carried out by skilled technicians who set up the machine based on your facility's specifications. We ensure the unit is correctly positioned (within 6x6x6 to 12x12x12 ft), calibrated, and tested for optimal performance before handover.Q: When is preventive maintenance required for this machine?

A: Preventive maintenance should be performed regularly, with the frequency depending on the machine's operating hours and capacity usage. Basic checks and cleaning should be done weekly, with more comprehensive servicing every three to six months for best results.Q: Where can the Water Bottling Plant Machine be delivered in India?

A: We offer delivery and installation services across India, reaching all major cities and industrial regions. Our support network ensures prompt assistance and service wherever your plant is located.Q: What are the main usage benefits of this water bottling plant machine?

A: Key benefits include high-speed automated operation, hygienic stainless steel construction, energy efficiency, and adaptability to various production scales. These features help streamline bottling processes, reduce labor costs, and increase output consistency.Q: How do the materials SS 304/316 enhance machine longevity?

A: SS 304/316 stainless steel is resistant to corrosion and chemical damage, making it ideal for water bottling applications. This ensures a longer lifespan for the machine and compliance with food safety standards.Q: What support is covered under the 1-year warranty?

A: The 1-year warranty covers repairs and replacement of defective components arising from manufacturing faults. Our service team provides on-site technical assistance to minimize downtime and keep your operations running smoothly.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Other Products in 'Bottle Filling Machine' category

|

DHARMANANDAN TECHNO PROJECTS PVT. LTD.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |