Industrial Packaged Drinking Water Plant

Price 580000.00 INR/ Unit

Industrial Packaged Drinking Water Plant Specification

- Usage & Applications

- Industrial Water Bottling, Beverages, Process Water

- Ph Level

- 6.5-8

- Water Out Conductivity

- Less than 10 S/cm

- Frequency

- 50/60 Hz

- Efficiency (%)

- 98%

- Power Consumption

- 2-10 kW (varies with capacity)

- Pump Type

- Centrifugal/High Pressure Pump

- Technology

- Reverse Osmosis (RO), UV, Ozone, UF

- Feature

- Corrosion Resistant, Low Maintenance, User Friendly

- Recycle Rate

- 98%

- Noise Level

- Below 70 dB

- Water in conductivity

- Less than 1500 S/cm

- Flow Rate

- 500 to 5000 LPH

- Product Type

- Packaged Drinking Water Plant

- Purity Level

- 99%

- Volume

- 500-5000 LPH (Liters per Hour)

- Power Source

- Electric

- Drive Type

- Electric Motor

- Automatic Grade

- Automatic

- Material

- Stainless Steel (SS 304/316)

- Water Source

- Borewell, Municipal Supply, River Water

- Voltage

- 220-440 V

- Filter Type

- Sand, Carbon, Micron, RO, UV

- Capacity

- 500 to 5000 Liters per Hour

- Installation Type

- Containerized/Skid Mounted

- Water Quality Monitoring

- Online TDS & Conductivity meter

- Pretreatment Unit

- Sand Filter, Pressure Filter

- Control System

- PLC, Digital Control Panel

- Net Weight

- Up to 1800 Kg

- Bottle Filling Capacity

- 200-1200 bottles/hour

- Pre-Filter

- 5 Micron and 10 Micron

- Service Support

- Onsite installation & training

- Alarm System

- Water level & error alarm

- Feed Pump Capacity

- Up to 2 HP

- Ambient Temperature

- 5-45°C

- Operation Mode

- Fully Automated

- Chlorine Dosing

- Automatic

- Disinfection Method

- UV, Ozone

- Pre Filtration

- Bag Filter, Cartridge Filter

- Dimensions

- Customizable as per requirement

- Maintenance Requirement

- Low

- Connection Type

- Flange/Threaded

Industrial Packaged Drinking Water Plant Trade Information

- Minimum Order Quantity

- 1 Set

- Supply Ability

- 30 Sets, Set Per Month

- Delivery Time

- 3 Week

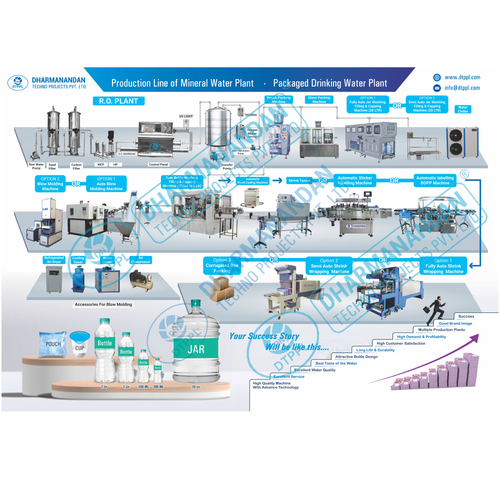

About Industrial Packaged Drinking Water Plant

Industrial Packaged Drinking Water Plant

We are offering best quality Industrial Packaged Drinking Water Plants, which are the precision-engineered ranges. The processes of these plants can provide an innocuous source of water supply that may be solids separation employing physical procedures such as settling as well as filtration, and chemical procedures such as coagulation and disinfection. These can remove suspended solids, viruses, fungi, minerals, bacteria, algae, and other chemical contaminants such as fertilizers. These come with optimized sequential procedure of filling, sealing and capping. These work through ionized water treatment and can monitor treated water quality.

Features:

-

Optimize sequential process of filling, capping and sealing

-

Ionized water treatment

-

Set of regeneration equipment, hydraulic ejectors, acid and alkali tanks and conductivity meter to monitor treated water quality

Advanced Purification Technologies

The plant incorporates multiple treatment stages, including sand and pressure filters, pre-filtration, and automatic chlorine dosing, followed by state-of-the-art UV and ozone disinfection. Reverse Osmosis ensures removal of dissolved impurities, delivering water with exceptional puritywell within industrial standards.

Intelligent, Fully Automated Operation

A PLC-enabled digital control panel orchestrates seamless plant operation, backed by automated alarms for water level and errors. Online TDS and conductivity meters guarantee real-time quality monitoring, while the customizable design allows integration into diverse industrial environments.

Customizable Throughput and Capacity

With capacities ranging from 500 to 5000 liters per hour and bottle filling rates of up to 1200 bottles/hour, the plant can be tailored to meet specific bottling or process water requirements. The containerized or skid-mounted options make installation straightforward and scalable for growing operations.

FAQs of Industrial Packaged Drinking Water Plant:

Q: How does the pretreatment system of the water plant enhance purification efficiency?

A: The pretreatment process uses sand and pressure filters, along with 5-micron and 10-micron pre-filters, bag, and cartridge filters to remove suspended solids and larger contaminants. This multi-stage filtration prepares the incoming water for advanced treatment, increasing overall purification efficiency and extending the lifespan of downstream membranes.Q: What control and monitoring features are included in this plant?

A: The plant features a sophisticated PLC-based digital control panel for fully automated operations, online TDS and conductivity meters for continuous water quality checks, plus alarm systems for water levels and operational errors. These controls ensure reliable performance with minimal manual intervention.Q: When is this packaged drinking water plant ideal for use?

A: This plant is ideal for industrial applications requiring high-purity water, such as water bottling, beverages, or process water. Its robust design supports continuous operation in ambient temperatures between 5-45C, with flexible installation for both new facilities and upgrades to existing lines.Q: Where can this packaged water plant be installed?

A: The plant is suitable for installation in factories, bottling units, or beverage production facilities. With customizable dimensions and containerized or skid-mount options, it can be tailored to fit available spaces and specific industrial needs across India and global locations.Q: What is the general process flow of water treatment in this plant?

A: Raw water from borewell, municipal, or surface sources passes through sand and pressure filters, bag and cartridge pre-filters, then receives automatic chlorine dosing. Subsequent RO, UV, and ozone treatment ensures microbial and chemical purity, after which water is monitored and bottled automatically.Q: How does the plant benefit users in terms of maintenance and operation?

A: Engineered for low maintenance and user-friendliness, the system uses corrosion-resistant stainless steel, automated controls, and online quality monitoring. These features reduce downtime, simplify routine checks, and ensure hygienic, high-quality water output with minimal manual labor.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Packaged Drinking Water Plant Category

Packaged Drinking Water Plant

Price 580000.00 INR / Unit

Minimum Order Quantity : 10 Units

Frequency : 50 Hz

Purity Level : 99.9%

Usage & Applications : Drinking Water, Commercial Bottling

Material : Stainless Steel (SS304/SS316)

Stainless Steel Packaged Drinking Water Plant

Price 2500000 INR / Unit

Minimum Order Quantity : 10 Units

Frequency : 5060 Hz

Purity Level : 99.9%

Usage & Applications : Bottling, Drinking, Industrial, Commercial

Material : Stainless Steel 304/316

Commercial Packaged Drinking Water Plant

Price 380000.00 INR / Unit

Minimum Order Quantity : 1 Set

Frequency : 50/60 Hertz (HZ)

Purity Level : As per WHO Guidelines

Usage & Applications : Industrial

Material : SS

Packaged Mineral Water Plant

Price 380000.00 INR / Unit

Minimum Order Quantity : 1 Unit

Frequency : 50/60 Hertz (HZ)

Purity Level : As per WHO Guidelines

Usage & Applications : Industrial

Material : Stainless Steel

|

DHARMANANDAN TECHNO PROJECTS PVT. LTD.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry