Turnkey Packaged Mineral Water Project

Product Details:

Turnkey Packaged Mineral Water Project Price And Quantity

- 2500000.00 - 10000000.00 INR/Unit

- 10 Unit

- 2500000 INR/Unit

Turnkey Packaged Mineral Water Project Trade Information

- Nhavaseva-Mumbai

- 30 Unit Per Year

- 2 Months

- Contact us for information regarding our sample policy

- Wooden with Fumigation certificate

- Asia, North America, South America, Western Europe, Middle East, Africa

- All India

Product Description

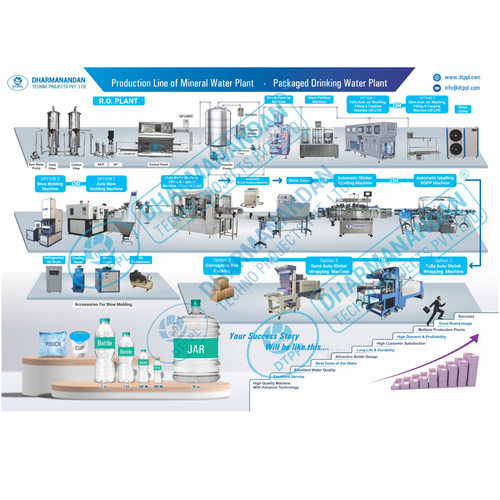

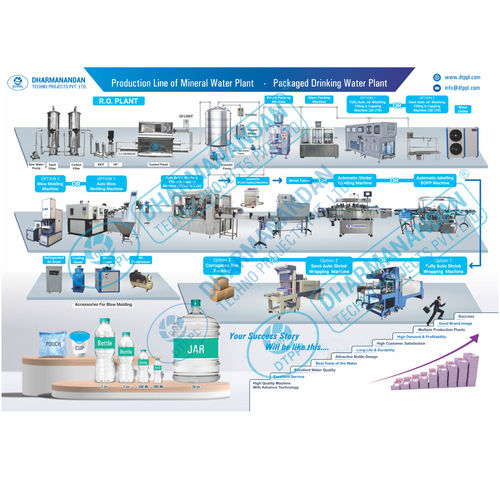

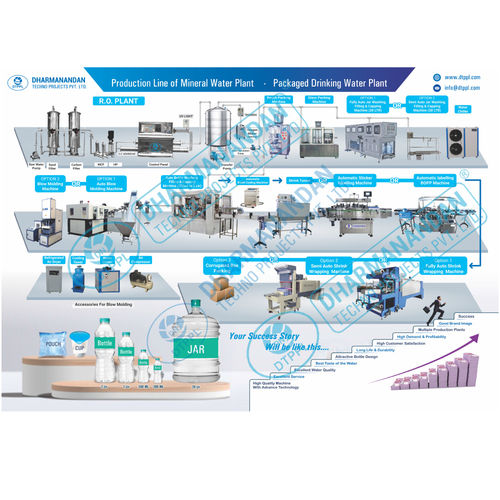

Turnkey Packaged Drinking Water Plants are used in wide-ranging industries for several purposes. These are appreciable for their zero maintenance features and are easy to use and connect. These are 100 distinct convenient source for all Mineral Water Plant systems accessories, including filtration, pre-treatment, and disinfection of water. Turnkey Packaged Drinking Water Plants have latest state of art design rendered with European technology. Provided with Micron Cartridge Filter Bag, Anthracite and Manufacturing stage wise inspection, these Turnkey Mineral Water Plants insure pure water.

We are involved in manufacturing and supplying Mineral Water Turnkey Projects. The product is used in varied industries for various purposes. The product is appreciated for its zero maintenance features. This economical product is easy to use and install.

To ensure 100 quality of Mineral Water Plant DTPPL designs and installs turnkey Water Treatment System Plant by incorporating the DTPPL equipments, parts & components. DTPPL offers a distinct convenient source for all Mineral Water Plant systems accessories, including pre treatment, filtration and disinfection of water. We manufacture the complete 360 degree Mineral Water Turnkey Projects.

Special Advantages of Turnkey Packaged Drinking Water Plant:

- Plant design on latest state of art an European technology, compact, decent

- We offered total imported systems

- Sealed Packed IS0-9001 Membranea Hydraunatics from California, U.S.A.

- Micron Cartridge Filter Bag

- Anthracite

- Manufacturing stage wise inspection

- After fabrication of the unit

- At the time of assembling of the unit

- While fitting of sealed pack Membrane

- Feel free to contact for Perfect Water Solutions.

Advanced Automation for Streamlined Operations

Our Turnkey Packaged Mineral Water Project leverages advanced PLC-based control systems to automate the entire bottling process, ensuring accuracy, consistency, and reduced manual intervention. The system can be tailored with various filling head options and bottle sizes to align with specific production goals. Its modular and compact plant structure maximizes space efficiency while facilitating scalable growth and straightforward maintenance.

Tailored Design and Flexible Production Capacity

Each project is custom-designed to accommodate your specific requirements, from voltage settings (380V/220V) and phase (three phase), to production capacity ranging from 1,000 to 24,000 bottles per hour. Whether you require small-scale operations or high-output production, our turnkey solutions adapt seamlessly. Bottle filling speeds and water purification capacities are configured according to your needs, guaranteeing optimal performance and quality.

FAQs of Turnkey Packaged Mineral Water Project:

Q: How does the turnkey packaged mineral water project ensure quality and hygiene during the bottling process?

A: The plant uses robust stainless steel for all key components and incorporates a state-of-the-art water purification system based on your design requirements. Automated PLC controls and multiple-head filling reduce contamination risks and support consistent, hygienic operations.Q: What production capacity options are available with this mineral water project?

A: Production capacities can be tailored from 1,000 up to 24,000 bottles per hour, depending on your operational needs. Both bottle size and filling speed are fully customizable to meet market demands.Q: When and where can the project be installed?

A: The turnkey project is available for deployment across India. Installation timelines vary based on plant size and configuration, but our modular structure and expert support ensure efficient setup and commissioning.Q: What is the process flow of water bottling in this plant?

A: The process begins with water purification, followed by automatic bottle rinsing, precise filling using multiple heads, capping, and packagingall managed by the integrated PLC control panel for streamlined operation.Q: How can the bottle sizes and filling speed be customized?

A: Bottle sizes from 200 ml to 2 litres and the corresponding filling speed are configured according to your particular requirements at the time of installation, ensuring the system matches your production goals.Q: What benefits does the turnkey packaged mineral water project provide to businesses?

A: The project offers efficiency, scalability, and reliable after-sales support. Its compact and modular design optimizes space, while automation reduces labor costs and enhances product consistencyideal for distributors, manufacturers, and wholesalers.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Other Products in 'Turnkey Drinking Water Plant' category

|

DHARMANANDAN TECHNO PROJECTS PVT. LTD.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Call Me Free

Call Me Free