Stainless Steel Packaged Drinking Water Plant

Price 2500000 INR/ Unit

Stainless Steel Packaged Drinking Water Plant Specification

- Pump Type

- Centrifugal/SS High Pressure Pump

- Frequency

- 50-60 Hz

- Efficiency (%)

- >90%

- Usage & Applications

- Bottling, Drinking, Industrial, Commercial

- Water Out Conductivity

- <10 us/cm

- Power Consumption

- 5-20 kW (depending on capacity)

- Noise Level

- Low Noise Operation < 60 dB

- Recycle Rate

- 70-80%

- Technology

- RO + UV + Ozone + Filtration

- Flow Rate

- 500-10,000 L/hr

- Ph Level

- 6.5-8

- Water in conductivity

- 100-1500 us/cm

- Feature

- Corrosion Resistant, Durable, Easy Operation

- Volume

- Customizable as per requirement

- Water Source

- Borewell, Municipal Water, Surface Water, River Water

- Power Source

- Electric

- Drive Type

- Electric Motor

- Product Type

- Packaged Drinking Water Plant

- Material

- Stainless Steel 304/316

- Purity Level

- 99.9%

- Automatic Grade

- Automatic

- Voltage

- 220-380 V

- Filter Type

- Multigrade Sand, Carbon, Micron

- Capacity

- 500 LPH - 10,000 LPH

- Installation Type

- Prefabricated, Skid Mounted

- Control Panel

- PLC/Automatic

- Disinfection

- UV & Ozonation

- CIP System

- Provided as per requirement

- Filling System

- Manual/Semi-Automatic/Automatic (As per requirement)

- Piping & Valves

- SS304/316 Food Grade

- Frame Structure

- SS Structure Frame

- Water Tank Material

- Stainless Steel

- Pretreatment

- Included (Sand Filter, Activated Carbon Filter, Micron Filter)

- Safety Features

- Overload Protection, Dry Run Protection

- Ambient Temperature

- 5°C to 45°C

- RO Membrane Brand

- Branded (Dow/Equivalent)

Stainless Steel Packaged Drinking Water Plant Trade Information

- Minimum Order Quantity

- 10 Units

- Supply Ability

- 30 Units Per Month

- Delivery Time

- 3 Week

About Stainless Steel Packaged Drinking Water Plant

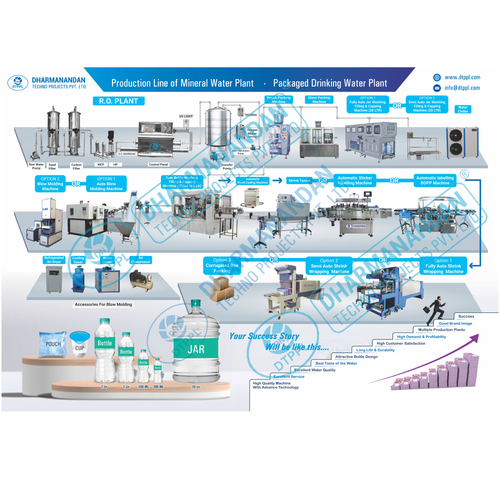

Turnkey Packaged Drinking Water Plants are used in wide-ranging industries for several purposes. These are appreciable for their zero maintenance features and are easy to use and connect. These are 100 distinct convenient source for all Mineral Water Plant systems accessories, including filtration, pre-treatment, and disinfection of water. Turnkey Packaged Drinking Water Plants have latest state of art design rendered with European technology. Provided with Micron Cartridge Filter Bag, Anthracite and Manufacturing stage wise inspection, these Turnkey Mineral Water Plants insure pure water.

We are involved in manufacturing and supplying Mineral Water Turnkey Projects. The product is used in varied industries for various purposes. The product is appreciated for its zero maintenance features. This economical product is easy to use and install.

To ensure 100 quality of Mineral Water Plant DTPPL designs and installs turnkey Water Treatment System Plant by incorporating the DTPPL equipments, parts & components. DTPPL offers a distinct convenient source for all Mineral Water Plant systems accessories, including pre treatment, filtration and disinfection of water. We manufacture the complete 360 degree Mineral Water Turnkey Projects.

Special Advantages of Turnkey Packaged Drinking Water Plant:

- Plant design on latest state of art an European technology, compact, decent

- We offered total imported systems

- Sealed Packed IS0-9001 Membranea Hydraunatics from California, U.S.A.

- Micron Cartridge Filter Bag

- Anthracite

- Manufacturing stage wise inspection

- After fabrication of the unit

- At the time of assembling of the unit

- While fitting of sealed pack Membrane

- Feel free to contact for Perfect Water Solutions.

Comprehensive Water Purification Process

The plant incorporates multistage filtration, including sand, activated carbon, and micron filters, to remove physical, chemical, and microbiological contaminants effectively. Reverse osmosis, UV disinfection, and ozonation guarantee a purified water output with conductivity levels below 10 s/cm, delivering safe and clear drinking water suitable for multiple uses.

Robust Stainless Steel Construction

The plant is crafted from high-grade SS304/316 for both internal and external components, ensuring high corrosion resistance and longevity. All piping and valves are food-grade, which maintains water purity throughout the process. Its sturdy structure is designed to handle ambient temperatures between 5C to 45C and delivers reliable performance in demanding industrial environments.

Flexible Design and User-Friendly Operation

From fully automatic to manual operation, the plant offers control flexibility via a modern PLC panel and options for automated or manual filling systems. The modular, skid-mounted construction allows for easy transportation and installation. Its low noise operation (<60 dB) and comprehensive safety features, such as overload and dry run protection, enhance user experience.

FAQs of Stainless Steel Packaged Drinking Water Plant:

Q: How does the Stainless Steel Packaged Drinking Water Plant purify water?

A: The plant uses a multi-stage process starting with sand, carbon, and micron filters for pretreatment, followed by reverse osmosis (RO) to remove dissolved solids. UV and ozonation systems provide final disinfection, ensuring water purity and safety.Q: What types of water sources can this plant handle?

A: This plant is compatible with borewell, municipal, surface, and river water sources, making it versatile for varied industrial, commercial, and drinking water needs.Q: When should the CIP (Cleaning in Place) system be used and why is it important?

A: The CIP system should be activated periodically or when indicated by the automated control system to clean membranes and filters. This process maintains membrane efficiency, prevents fouling, and ensures the plant delivers consistently high water quality.Q: Where can the packaged plant be installed?

A: Thanks to its prefabricated, skid-mounted design, the plant can be installed at bottling units, commercial sites, industrial facilities, or wherever clean water processing is required. Its modular structure enables straightforward on-site setup.Q: What are the benefits of using a stainless steel structure for this drinking water plant?

A: Stainless steel SS304/316 provides robust corrosion resistance, durability in diverse conditions, and maintains hygiene by preventing contamination. This ensures long service life and low maintenance.Q: How easy is it to operate and maintain the plant?

A: With an automatic, PLC-based control panel and clear status displays, the plant is simple to operate and monitor. Integrated safety features and an efficient CIP system reduce maintenance effort, enabling smooth operation with minimal supervision.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Packaged Drinking Water Plant Category

Industrial Packaged Drinking Water Plant

Price 580000.00 INR / Unit

Minimum Order Quantity : 1 Set

Automatic Grade : Other, Automatic

Feature : Corrosion Resistant, Low Maintenance, User Friendly

Voltage : 220440 V

Purity Level : 99%

Packaged Drinking Water Plant

Price 580000.00 INR / Unit

Minimum Order Quantity : 10 Units

Automatic Grade : Other, Automatic

Feature : Low Maintenance, High Output, Compact Design

Voltage : 220380 V

Purity Level : 99.9%

Commercial Packaged Drinking Water Plant

Price 380000.00 INR / Unit

Minimum Order Quantity : 1 Set

Automatic Grade : Full Automatic

Feature : High Filtration Efficiency, EnergyEfficient Design, Automated Controls

Voltage : 220 440 Volt (v)

Purity Level : As per WHO Guidelines

Packaged Mineral Water Plant

Price 380000.00 INR / Unit

Minimum Order Quantity : 1 Unit

Automatic Grade : Full Automatic

Feature : High Filtration Efficiency, EnergyEfficient Design, Automated Controls

Voltage : 220 440 Volt (v)

Purity Level : As per WHO Guidelines

|

DHARMANANDAN TECHNO PROJECTS PVT. LTD.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry

Call Me Free

Call Me Free