Soft Drink Plant

1000000.00 INR

Product Details:

- Motor Power 3 HP

- Temperature Range 5C - 40C

- Driven Type Motor Driven

- Accessories Filling Nozzles, Conveyor, Rinsing Machine, Capping Unit

- Speed Adjustable

- Plastic Processed PET

- Production Capacity Customizable

- Click to view more

X

Soft Drink Plant Price And Quantity

- 1000000.00 INR

- 10

Soft Drink Plant Product Specifications

- Silver

- Yes

- 5C - 40C

- 3 HP

- Automatic

- Electric

- PLC Control

- 220-440 V

- PET

- Customizable

- Corrosion Resistant, High Efficiency, Low Maintenance, Easy Operation

- Filling Nozzles, Conveyor, Rinsing Machine, Capping Unit

- Varies with Capacity

- Motor Driven

- 8 kW

- Adjustable

- Onsite Installation by Technical Team

- Fully Automatic

- SDP-6000

- Soft Drink Plant

- 1800 kg

- Fully Automatic Bottling Plant

- Stainless Steel

- 3800 x 1200 x 2100 mm

- 98%

- 500 to 6000 Bottles/Hour

- 50/60 Hz

- Carbonated Drinks, Soft Drinks, Soda Water

- Polished

Soft Drink Plant Trade Information

- South America, Middle East, Africa, Asia, North America

Product Description

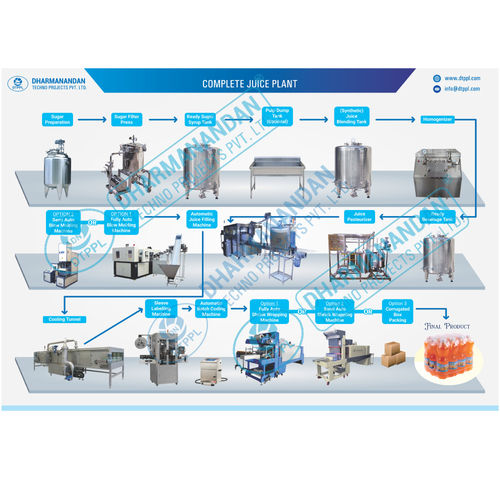

Soft Drink Plant provided by our company, is widely used for the production of soft drinks which contains less calories and no sugar at all. This plant is mainly preferred for its unique features like easy to operate, power efficient, long lasing and minimum maintenance. This plant is very effective and safe to use. Soft Drink Plant is clinically tested under various parameters to ensure its high quality and excellent working. This plant is very cost effective and can be easily availed at nominal pricing, by our valued customers, in bulk quantities.

Versatile Production Capability

The SDP-6000 Soft Drink Plant supports a wide range of bottle sizes, from 200 ml to 2 liters, allowing flexibility for various market demands. The plant operates at an impressive capacity, producing between 500 and 6000 bottles per hour, depending on configuration. Its customizable production setup enables businesses to cater to different product lines and volumes with ease.

Advanced Automation and Control

Featuring a PLC-controlled system with a user-friendly touch screen, the plant offers precise control over filling parameters and ensures consistent product quality. The automated process minimizes manual intervention, optimizing efficiency, and reducing operational errors. Continuous monitoring enables operators to make quick adjustments, promoting uninterrupted production cycles.

Durability and Hygienic Design

Constructed from corrosion-resistant, polished stainless steel, the plant meets stringent hygiene standards for the beverage industry. The robust build ensures longevity and reliable operation under demanding production environments. Low maintenance requirements reduce downtime and operating costs, increasing overall productivity.

FAQs of Soft Drink Plant:

Q: How does the SDP-6000 Soft Drink Plant ensure filling accuracy during operation?

A: The plant uses PLC-controlled automation and precision-engineered filling nozzles to maintain a filling accuracy of 1%. This system continuously monitors flow rates and adjusts the process in real-time, minimizing product loss and ensuring consistent bottle volumes.Q: What types of beverages can be processed with this soft drink plant?

A: This bottling plant is specially designed for carbonated drinks, soft drinks, and soda water. Its adaptability also accommodates production of beverages packaged in PET plastic bottles ranging from 200 ml to 2 liters.Q: When is onsite installation and technical support provided?

A: Onsite installation is arranged by the manufacturers technical team upon purchase. Support includes equipment setup, training for operators, and initial production assistance to ensure seamless integration into your facility.Q: Where can the SDP-6000 Soft Drink Plant be installed?

A: The plant is suitable for installation in beverage production facilities across India and beyond. Its compact design (3800 x 1200 x 2100 mm) allows it to fit efficiently within standard industrial spaces, making it ideal for manufacturers, exporters, and bottling service providers.Q: What is the process involved in operating this fully automatic plant?

A: Operation involves automated rinsing, filling, and capping of PET bottles. Bottles pass through a conveyor, are washed, filled with the beverage using high-precision nozzles, and then capped securely. All operations are managed via a touch screen control panel, enabling easy monitoring and adjustments.Q: How is the plant maintained and what are its advantages in terms of usage?

A: The stainless steel construction and minimalistic design make cleaning and maintenance simple. Its engineered for low maintenance, high efficiency (operating at 98%), and quiet performance ( 70 dB). Advanced automation reduces manual labor, optimizes operational costs, and provides long-term reliability.Q: What are the main benefits of choosing the SDP-6000 model for beverage production?

A: Key benefits include high production efficiency, customizable capacity, precise filling accuracy, robust and hygienic construction, low operating noise, and simple, touch screen-based operation. Its fully automatic system saves both time and labor, making it a strong investment for beverage manufacturing businesses.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Other Products in 'Soft Drink Plant' category

|

DHARMANANDAN TECHNO PROJECTS PVT. LTD.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Call Me Free

Call Me Free