Plastic Bottle Making Machine

765000.00 INR

Product Details:

- Cooling System Water/Cooling System

- Lubricating System Auto lubrication system

- Power Rating Variable based on usage

- Features Automatic operation durable design

- Frequency 50 Hz

- Machine Type Plastic Bottle Making Machine

- Connectivity Options Standard electrical connections

- Click to view more

X

Plastic Bottle Making Machine Price And Quantity

- 765000.00 INR

- 10

Plastic Bottle Making Machine Product Specifications

- High production capacity

- Heavy-duty machine weight not specified

- Auto lubrication system

- Manufacturers standard warranty

- Paint-coated surface

- Advanced manufacturing technology

- Water/Cooling System

- Automatic operation durable design

- Variable based on usage

- Gray

- Plastic Bottle Making Machine

- Plastic Bottle Making Machine

- Standard electrical connections

- 50 Hz

- Approximate dimensions provided by manufacturer

- Defined by machine specs

- Steel frame

- Fully Automatic

- Low

- Ambient conditions

- Specified in machine data

- Bottle production for packaging industries

- High

- Electric

- 220-240V

- PLC

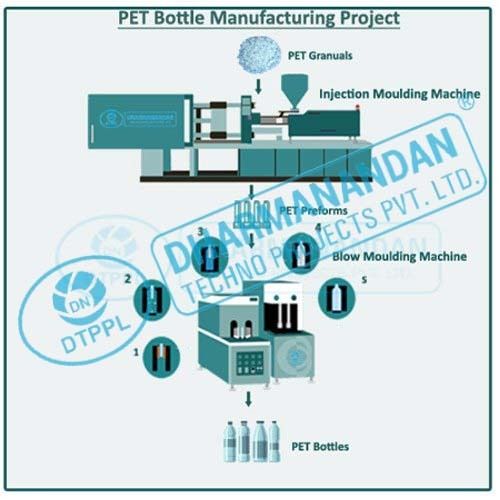

Product Description

Plastic Bottle Making Machine

Product details

|

Raw Material |

PET Preform |

|

Brand |

Dharmanandan |

|

Power Consumption |

36 HP |

|

Production Capacity |

1100/hr |

|

Automation Grade |

Semi Automatic |

|

Phase |

3 |

|

Mould Cavity |

2 |

High-Capacity, Reliable Production

This machine streamlines the bottle production process, delivering a high output with strict accuracy, helping meet the demands of large-scale packaging industries. Its advanced features and automatic operation reduce labor needs while ensuring reliability and consistency in every batch.

Durable, Modern Engineering

Constructed with a heavy-duty steel frame and advanced manufacturing components, the machine includes a paint-coated finish for enhanced durability. The automated lubrication and sophisticated cooling systems support prolonged operation, maximizing uptime and minimizing maintenance requirements.

FAQ's of Plastic Bottle Making Machine:

Q: How does the Plastic Bottle Making Machine operate automatically?

A: The machine utilizes a PLC control system for seamless, fully automatic operation, handling bottle production from start to finish with minimal manual intervention. This ensures high efficiency, consistent quality, and reduced production errors.Q: What are the main applications of this bottle making machine?

A: Primarily, the machine is used for producing plastic bottles for the packaging industry, including beverages, personal care products, and household goods. It is suitable for manufacturers, exporters, distributors, and suppliers seeking reliable packaging solutions.Q: What is the benefit of the auto lubrication and water cooling systems?

A: The integrated auto lubrication and water cooling systems ensure efficient performance, reduce wear and tear, and help prevent overheating, thereby extending the machine's lifespan and minimizing unscheduled downtime.Q: Where can the machine be used and who typically uses it?

A: This machine is well-suited for industrial environments across India, particularly in packaging factories and production units. It is widely adopted by manufacturers, wholesalers, service providers, and suppliers.Q: What is the process for producing bottles with this machine?

A: The process starts with feeding raw plastic material into the machine, which then uses advanced technology and controlled pressure to mold and cool bottles to the desired shape and size, all orchestrated via its automated control system.Q: What warranty and after-sales support are available?

A: The machine is covered under the manufacturer's standard warranty, ensuring support for repairs and maintenance as per warranty terms. Additional services can be provided by authorized service partners.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Other Products in 'Bottle Making Machine' category

|

DHARMANANDAN TECHNO PROJECTS PVT. LTD.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |